Get notified when this item comes back in stock.

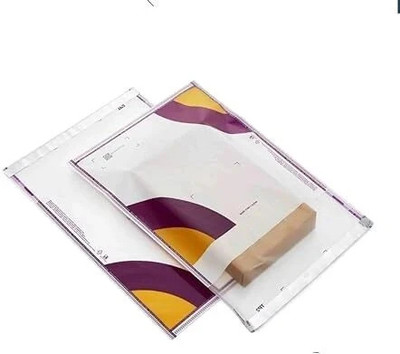

Bleus Corrugated Paper, Cardboard Tuck-in Box, Size-6x1x8", L-6 B-1, H-8, Inch Packaging Box (Pack of 50 Brown)

Share

Bleus Corrugated Paper, Cardboard Tuck-in Box, Size-6x1x8", L-6 B-1, H-8, Inch Packaging Box (Pack of 50 Brown)

Be the first to Review this product

₹499

₹1,399

64% off

Sold Out

This item is currently out of stock

Highlights

- Type: Corrugated

- Material: Paper, Cardboard

- Number of Compartments: 1

- W x H x D: 15 cm x 20 cm x 2.5 cm

- Pack of 50

Seller

Description

A 3-ply corrugated box is a type of packaging material commonly used for shipping and transporting goods. It is constructed with three layers of paperboard, each serving a specific purpose to provide strength, durability, and protection to the contents inside. The three layers typically consist of two flat outer layers, known as liners, and a wavy inner layer, known as the corrugating medium.

Liners: These are the flat outer layers of the corrugated box, and they sandwich the corrugating medium. The liners provide the box with stability and a smooth surface for printing. The liner materials are usually made of paperboard and can vary in thickness depending on the intended use and the level of protection required.

Corrugating Medium: This is the wavy layer that is located between the liners. It is responsible for the strength and rigidity of the box. The corrugating medium is often made from a type of paper known as kraft paper, which is fluted to create the characteristic corrugated pattern. The flutes can vary in size and shape, and this variation affects the box's strength and cushioning properties.

The combination of the three layers creates a structure that is both lightweight and strong, making 3-ply corrugated boxes ideal for protecting goods during transportation. These boxes are widely used in the packaging industry for shipping a variety of products, ranging from consumer goods to industrial components.

Corrugated boxes are popular due to their versatility, cost-effectiveness, and ability to be recycled. They come in various sizes and can be customized to meet specific packaging requirements. The 3-ply design strikes a balance between strength and flexibility, making it suitable for a wide range of applications.

Read More

Specifications

General

| Brand |

|

| Model Number |

|

| Type |

|

| Box Material |

|

| Used For |

|

| Color |

|

| Technology Used |

|

| Net Quantity |

|

Body And Design Features

| Pattern |

|

| Foldable |

|

| Closure |

|

| Staple and Rivet Less |

|

| Number of Compartments |

|

| Hand Holes |

|

Additional Features

| Recyclable |

|

| Reusable |

|

| Moisture Resistant |

|

| Crust Resistant |

|

| Eco-Friendly |

|

Dimensions

| Box Width |

|

| Box Height |

|

| Box Depth |

|

Be the first to ask about this product

Safe and Secure Payments.Easy returns.100% Authentic products.

Back to top